Your vehicle’s braking system is a critical component for ensuring your safety on the road. Understanding the warning signs of worn-out brakes can help you avoid potentially dangerous situations and costly repairs. From strange noises to changes in pedal feel, your car communicates its braking system’s health in various ways. Recognizing these signals early can make the difference between a routine maintenance visit and a major overhaul.

Auditory indicators of brake wear: decoding squeals and grinding noises

One of the most noticeable signs that your brakes may need attention is the sound they make when applied. Unusual noises are often the first indication that something isn’t quite right with your braking system. Pay close attention to these auditory cues, as they can provide valuable information about the condition of your brakes.

A high-pitched squealing noise when you apply the brakes is typically one of the earliest warning signs. This sound is often caused by a small metal indicator that’s built into the brake pad. When the pad material wears down to a certain thickness, this indicator makes contact with the rotor, creating the squealing noise. It’s essentially your car’s way of telling you it’s time for a brake inspection.

If you ignore the initial squealing, you may soon hear a more ominous sound: grinding. A grinding noise typically indicates that the brake pads have worn completely through, and metal is now making direct contact with metal. This situation can quickly lead to damage of the brake rotors, which are much more expensive to replace than pads alone.

Early detection of brake wear through auditory signals can save you from costly repairs and ensure your vehicle maintains optimal stopping power.

It’s important to note that not all brake noises indicate a problem. New brakes may squeal slightly as they bed in, and occasional squeaks can occur due to environmental factors like humidity or dust. However, persistent or changing noises should always be investigated by a professional.

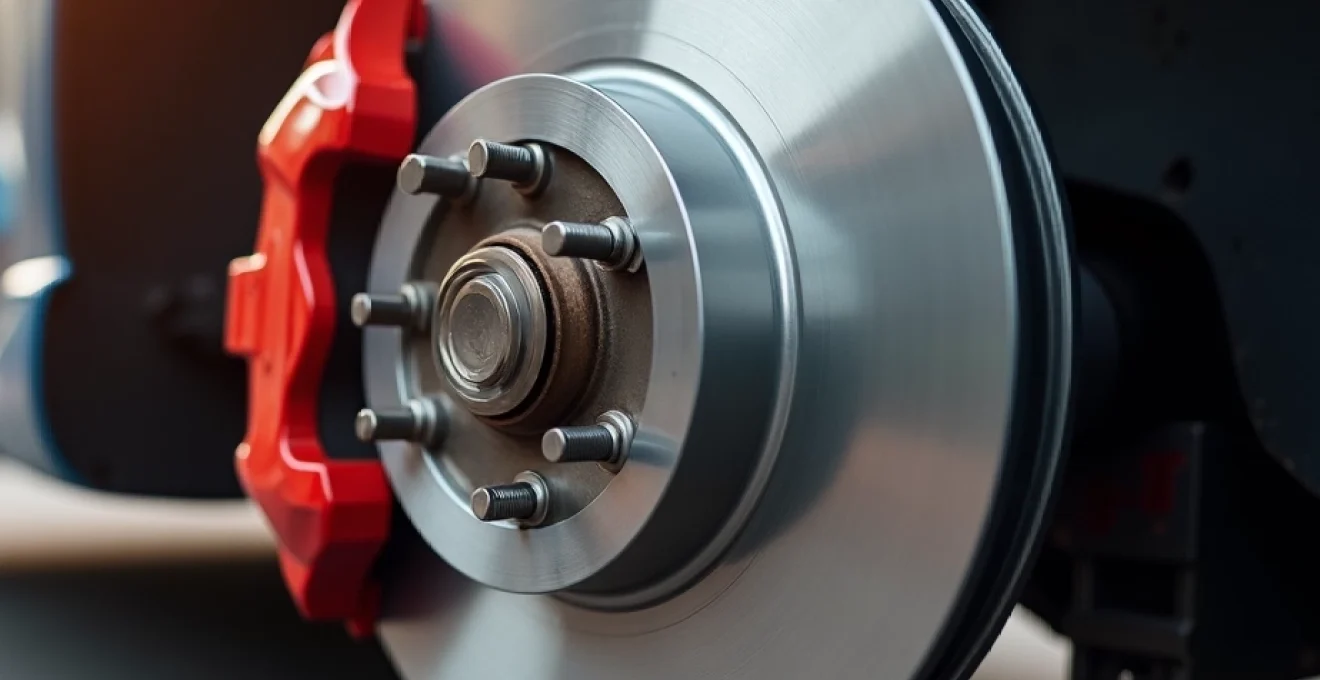

Visual cues: interpreting brake rotor and pad conditions

While auditory signals are often the first indicator of brake wear, visual inspection can provide concrete evidence of your brakes’ condition. Regular visual checks can help you catch potential issues before they become serious problems. Let’s explore some key visual cues to look out for when assessing your brake system’s health.

Scoring patterns on brake rotors: causes and implications

Brake rotors should ideally have a smooth, even surface. However, over time, you might notice visible grooves or scoring on the rotor surface. These patterns can be caused by several factors, including normal wear and tear, contamination from brake pad material, or damage from worn-out pads.

Light scoring is often normal and may not affect brake performance significantly. However, deep grooves or uneven wear patterns can indicate more serious issues. These can lead to reduced braking efficiency and may cause vibrations or pulsations when braking. If you notice significant scoring on your rotors, it’s time to have them inspected by a professional.

Brake pad thickness: measuring with caliper gauges

Brake pad thickness is a critical indicator of your braking system’s health. Most brake pads start with about 12 millimeters of friction material and should be replaced when they wear down to about 3-4 millimeters. While a visual inspection can give you a general idea, using a caliper gauge provides a more accurate measurement.

To measure your brake pad thickness:

- Locate the brake caliper and pad assembly

- Position the caliper gauge to measure the pad’s friction material

- Take multiple measurements across the pad for accuracy

- Compare the results to manufacturer specifications

If your brake pads are approaching the minimum thickness, it’s time to schedule a replacement. Remember, driving with overly worn pads can damage other components of your braking system, leading to more expensive repairs.

Brake dust accumulation: normal vs. excessive levels

Brake dust is a natural byproduct of your braking system’s operation. It’s created as the brake pad material wears down and is deposited on your wheels. While some brake dust is normal, excessive accumulation can indicate that your brake pads are wearing more quickly than they should.

Pay attention to how quickly brake dust builds up on your wheels. If you’re noticing a significant increase in dust accumulation between cleanings, or if one wheel seems to be collecting more dust than the others, it could be a sign of uneven brake wear or a stuck caliper. These issues warrant a professional inspection to ensure your braking system is functioning correctly.

Rotor lip formation: indicator of advanced wear

As brake rotors wear down, they can develop a lip or ridge around their outer edge. This lip forms because the brake pad doesn’t make contact with the entire surface of the rotor, leading to uneven wear. A pronounced lip is a clear sign that your rotors have worn significantly and may need to be replaced or resurfaced.

To check for a rotor lip:

- Visually inspect the outer edge of the rotor

- Run your finger along the edge to feel for a raised lip

- Compare the thickness of the lip to the rest of the rotor surface

If you can feel a significant lip, it’s time to have your rotors inspected. Driving with severely worn rotors can compromise your vehicle’s braking performance and safety.

Pedal feedback: analyzing brake response and feel

The way your brake pedal feels under your foot can provide valuable insights into the health of your braking system. Changes in pedal response or unusual sensations during braking are often early indicators of developing issues. Let’s explore some common pedal feedback symptoms and what they might mean for your brakes.

Brake pedal pulsation: warped rotor diagnosis

If you feel a pulsation or vibration through the brake pedal when slowing down, it’s often a sign of warped brake rotors. This pulsation occurs because the brake pads are not making consistent contact with the rotor surface as it spins. Warped rotors can be caused by several factors, including:

- Extreme temperature changes from heavy braking

- Uneven tightening of lug nuts

- Extended periods of disuse

- Manufacturing defects

Mild pulsation might be tolerable, but significant vibration can affect braking performance and should be addressed promptly. In many cases, warped rotors can be resurfaced, but severe warping may require rotor replacement.

Pedal travel: identifying hydraulic system issues

The distance your brake pedal travels before engaging the brakes is another important diagnostic tool. If you notice that you need to push the pedal further down than usual before feeling resistance, it could indicate a problem with your brake system’s hydraulics.

Increased pedal travel, often described as a “soft” or “spongy” brake pedal, can be caused by:

- Air in the brake lines

- Low brake fluid levels

- Worn brake pads

- Leaks in the hydraulic system

Any change in pedal feel should be investigated promptly, as it can significantly affect your vehicle’s stopping power and safety.

ABS engagement: abnormal activation patterns

The Anti-lock Braking System (ABS) is designed to prevent wheel lock-up during hard braking. Under normal conditions, you might feel a slight pulsation in the brake pedal when ABS activates on slippery surfaces. However, if you notice ABS engaging during normal braking conditions or at low speeds, it could indicate a problem with the system.

Abnormal ABS activation can be caused by:

- Faulty wheel speed sensors

- Damaged ABS control module

- Issues with the hydraulic control unit

If you’re experiencing unusual ABS behavior, it’s crucial to have your vehicle inspected by a qualified technician. Proper ABS function is essential for maintaining control during emergency braking situations.

Dashboard warnings: interpreting brake system alerts

Modern vehicles are equipped with sophisticated onboard diagnostic systems that can alert you to potential brake issues before they become serious problems. Understanding these dashboard warnings can help you address brake system issues promptly, potentially saving you from costly repairs or dangerous driving conditions.

The most common brake-related warning light is the brake system warning light, which typically appears as a circle with an exclamation point inside or the word “BRAKE” in capital letters. This light can indicate several issues, including:

- Low brake fluid levels

- Engaged parking brake

- Problems with the brake hydraulic system

- Imbalance in the brake system pressure

If this light comes on while driving, it’s important to safely pull over and check your brake fluid levels. If the fluid is low, topping it off may resolve the issue temporarily, but you should still have your system checked for leaks.

Another important indicator is the ABS warning light. This light typically looks like the letters “ABS” enclosed in a circle. When illuminated, it suggests a problem with the anti-lock braking system. While your regular brakes should still function, the anti-lock feature may be compromised, which could affect your vehicle’s stability during hard braking.

Never ignore dashboard warning lights related to your braking system. These alerts are designed to catch problems early, potentially saving you from more serious issues down the road.

Some vehicles also have brake pad wear indicators. These might appear as a separate warning light or be integrated into the vehicle’s information display. When this indicator activates, it’s time to have your brake pads inspected and likely replaced.

Performance changes: recognizing diminished braking efficiency

While visual and auditory cues are important, the overall performance of your braking system is perhaps the most critical factor to monitor. Changes in how your vehicle responds to brake application can be subtle at first but may indicate developing issues that require attention.

Increased stopping distance: causes and measurements

One of the most noticeable signs of diminishing brake performance is an increase in stopping distance. If you find that your vehicle is taking longer to come to a complete stop than it used to, it’s time to have your brakes inspected.

Increased stopping distance can be caused by several factors:

- Worn brake pads or shoes

- Glazed or contaminated brake components

- Problems with the brake hydraulic system

- Issues with brake rotors or drums

To roughly measure your stopping distance, find a safe, empty stretch of road and choose a fixed point. Apply your brakes firmly at a specific speed (e.g., 30 mph) and note how far past your chosen point you stop. Compare this to your vehicle’s typical performance or manufacturer specifications.

Brake fade: Heat-Induced performance degradation

Brake fade occurs when your brakes overheat, typically due to prolonged or repeated hard braking. As the brake components heat up, they become less effective at creating the friction necessary to slow your vehicle. This can result in a spongy brake pedal feel and reduced stopping power.

Brake fade is most commonly experienced during:

- Descending long, steep hills

- Towing heavy loads

- Track driving or other high-performance situations

If you frequently encounter conditions that could lead to brake fade, consider upgrading to high-performance brake components designed to handle higher temperatures.

Uneven braking: diagnosing caliper issues

If your vehicle pulls to one side when braking, it could indicate uneven brake wear or a problem with one of your brake calipers. A stuck caliper can cause one wheel to brake more aggressively than the others, leading to this pulling sensation.

To diagnose uneven braking:

- Find a safe, empty area to test your brakes

- Accelerate to a moderate speed and apply the brakes firmly

- Pay attention to any pulling or veering to one side

- Repeat the test several times to confirm the behavior

If you consistently experience uneven braking, have your brake system inspected as soon as possible. Driving with a stuck caliper can lead to accelerated wear on brake components and tires, as well as reduced braking performance.

Professional inspection: key components and wear thresholds

While many brake issues can be identified through careful observation and self-inspection, a professional brake inspection is crucial for maintaining optimal brake performance and safety. Trained technicians have the tools and expertise to thoroughly evaluate your brake system and identify potential issues before they become serious problems.

Brake fluid analysis: moisture content and contamination

Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This moisture can lead to corrosion within the brake system and reduce the fluid’s boiling point, potentially causing brake fade under extreme conditions. During a professional inspection, technicians will:

- Check the brake fluid level

- Assess the fluid’s condition and color

- Test for moisture content and contamination

- Recommend fluid replacement if necessary

Most manufacturers recommend changing brake fluid every two years or 30,000 miles, whichever comes first. However, this can vary based on driving conditions and vehicle usage.

Caliper functionality: sticking pistons and seal integrity

Brake calipers are responsible for pressing the brake pads against the rotors to create friction. Over time, caliper pistons can become sticky or seals can degrade, leading to uneven braking or reduced performance. During an inspection, a technician will:

- Check for smooth caliper piston movement

- Inspect caliper seals for signs of leakage

- Assess caliper slide pins for proper lubrication and movement

- Look for signs of corrosion or damage to the caliper body

Properly functioning calipers are essential for even brake pad wear and consistent braking performance.

Brake line inspection: corrosion and leak detection

Brake lines carry the hydraulic fluid that transfers force from the brake pedal to the wheel brakes. These lines can corrode over time, especially in areas where road salt is used. A professional inspection will include:

- Visual inspection of brake lines for signs of corrosion or damage

- Checking for any fluid leaks at connection points

- Assessment of brake hose flexibility and condition

- Verification of proper brake line routing and secure mounting

Any signs of brake line deterioration should be addressed immediately, as a brake line failure can result in a complete loss of braking ability.

Rotor thickness measurement: using micrometers

Brake rotors wear down over time and have a minimum thickness specification set by the manufacturer. A professional will use precision tools to measure rotor thickness and determine if they need resurfacing or replacement. This process typically involves:

- Removing the wheel to access the rotor

- Using a micrometer to measure rotor thickness at multiple points

- Comparing measurements to manufacturer specifications

- Assessing rotor surface condition for scoring or other damage

Rotors that are too thin or severely scored can compromise braking performance and should be replaced.

Rotor thickness is critical for proper brake function. If rotors become too thin, they can warp or crack under the stress of braking, leading to reduced performance and potential safety hazards. Professional measurements ensure your rotors meet safety standards and perform optimally.

Regular professional inspections, combined with attentiveness to the warning signs we’ve discussed, form a comprehensive approach to brake maintenance. By staying proactive about your vehicle’s brake health, you can ensure safety, avoid costly repairs, and maintain optimal vehicle performance.